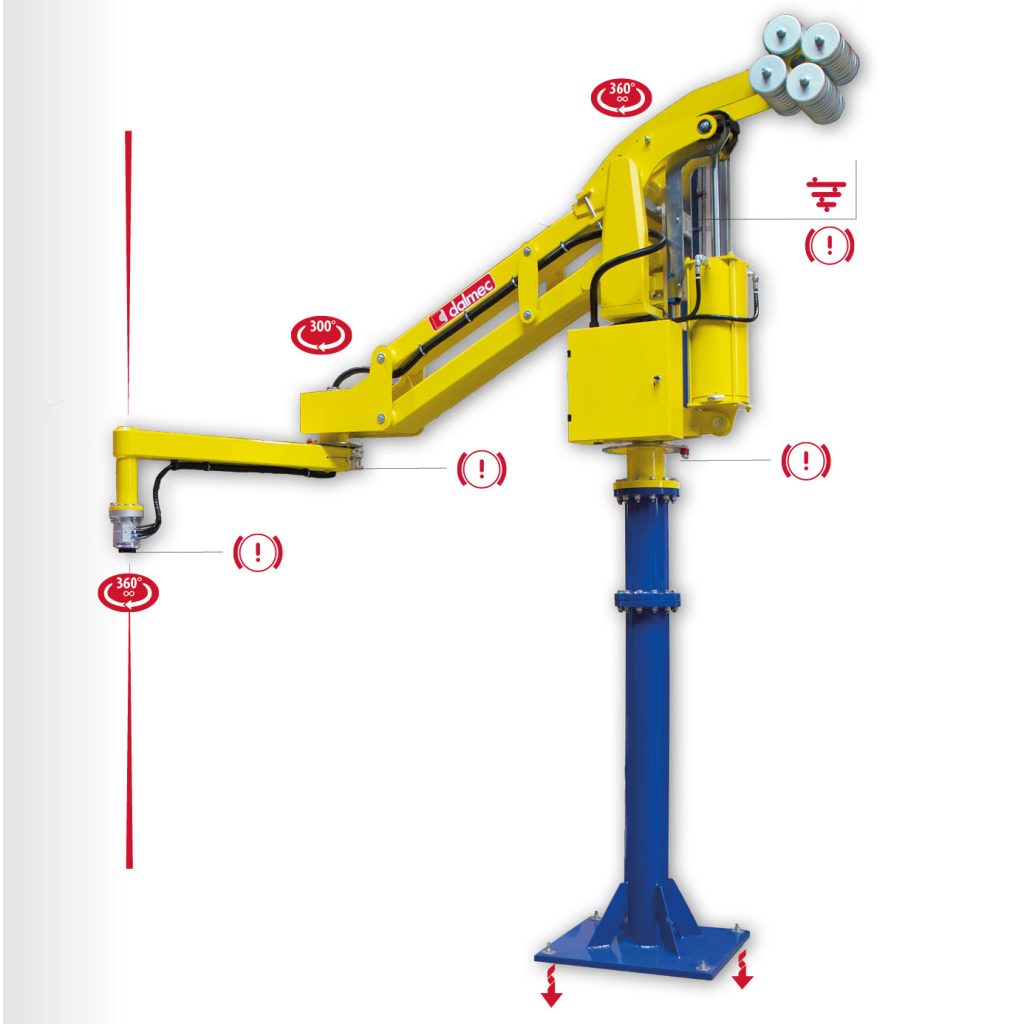

Maxipartner

- Manipulators with Rigid Arms

Features

- Max weight capacity: 900

- Max working radius: 4500 mm

- Vertical lift: 2200 mm

- Working pressure: 0.7 ÷ 0.8 Mpa

- Control system: solely pneumatic

- Supply: filtrated compressed-air (40 µm), not lubricated

- Max vertical lifting speed: 0,5 meters/second

- Working temperature: from +0° to +45° C

- Noise level: <70 dB

- Consumption: from 100 Nl ÷ 400 Nl per working cycle

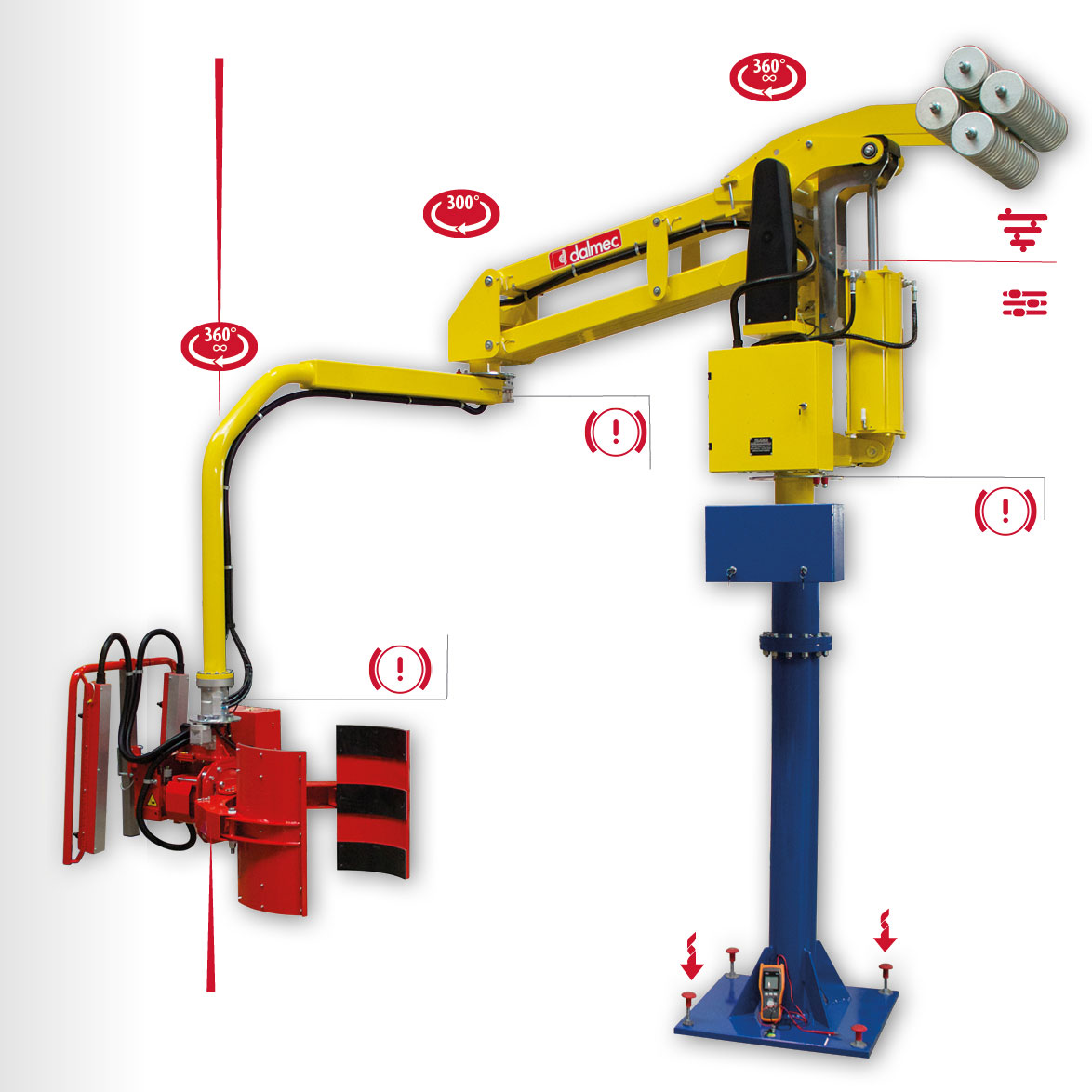

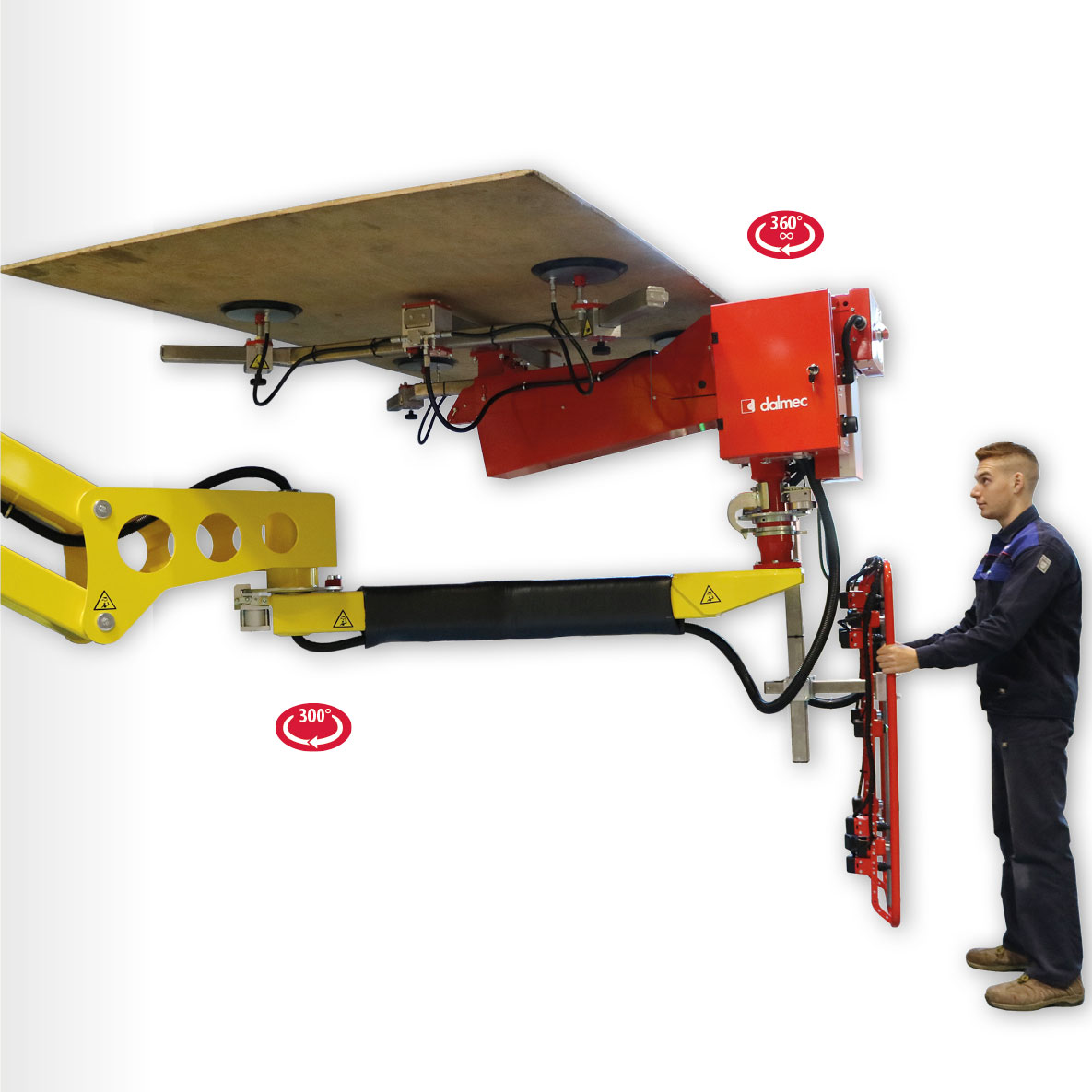

- Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution

- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

- Inox Column

- Inox Fixed Overhead

- Inox Overhead Running

- Overhead Running

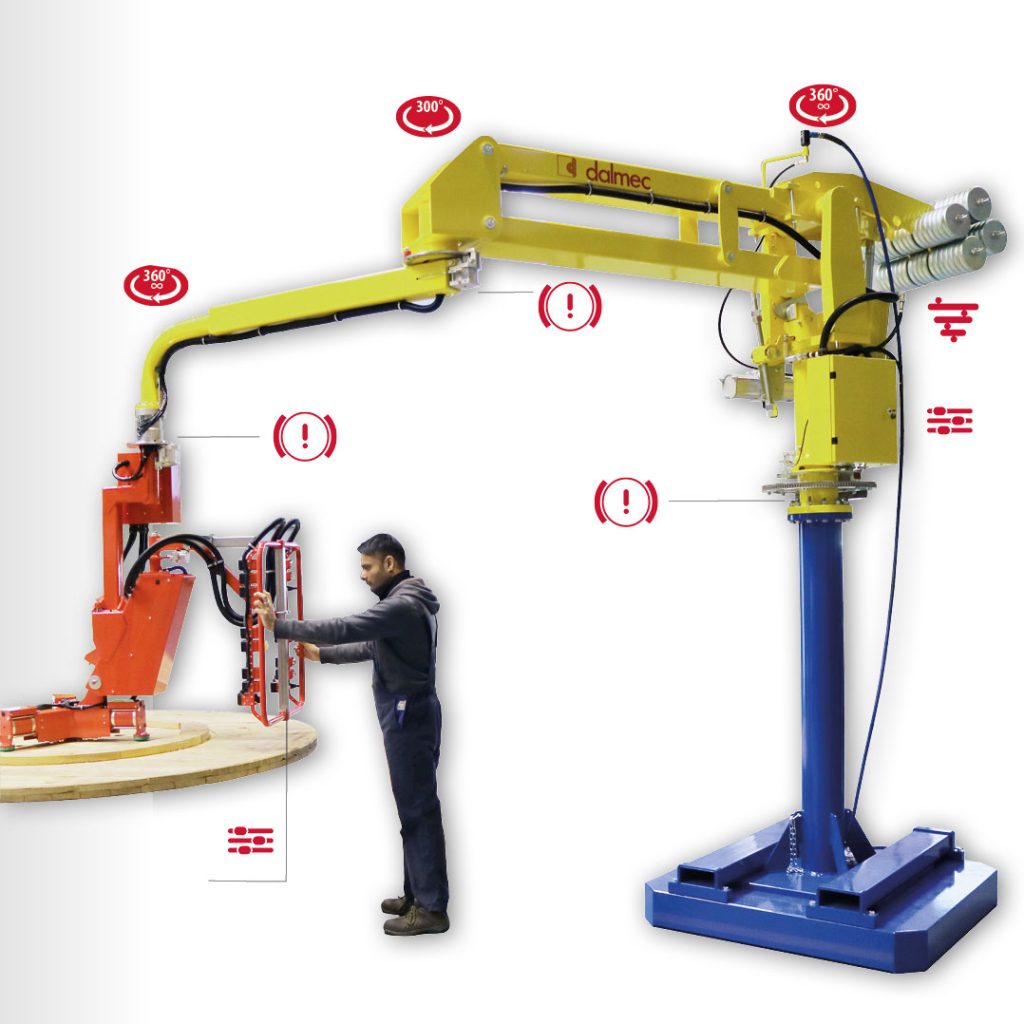

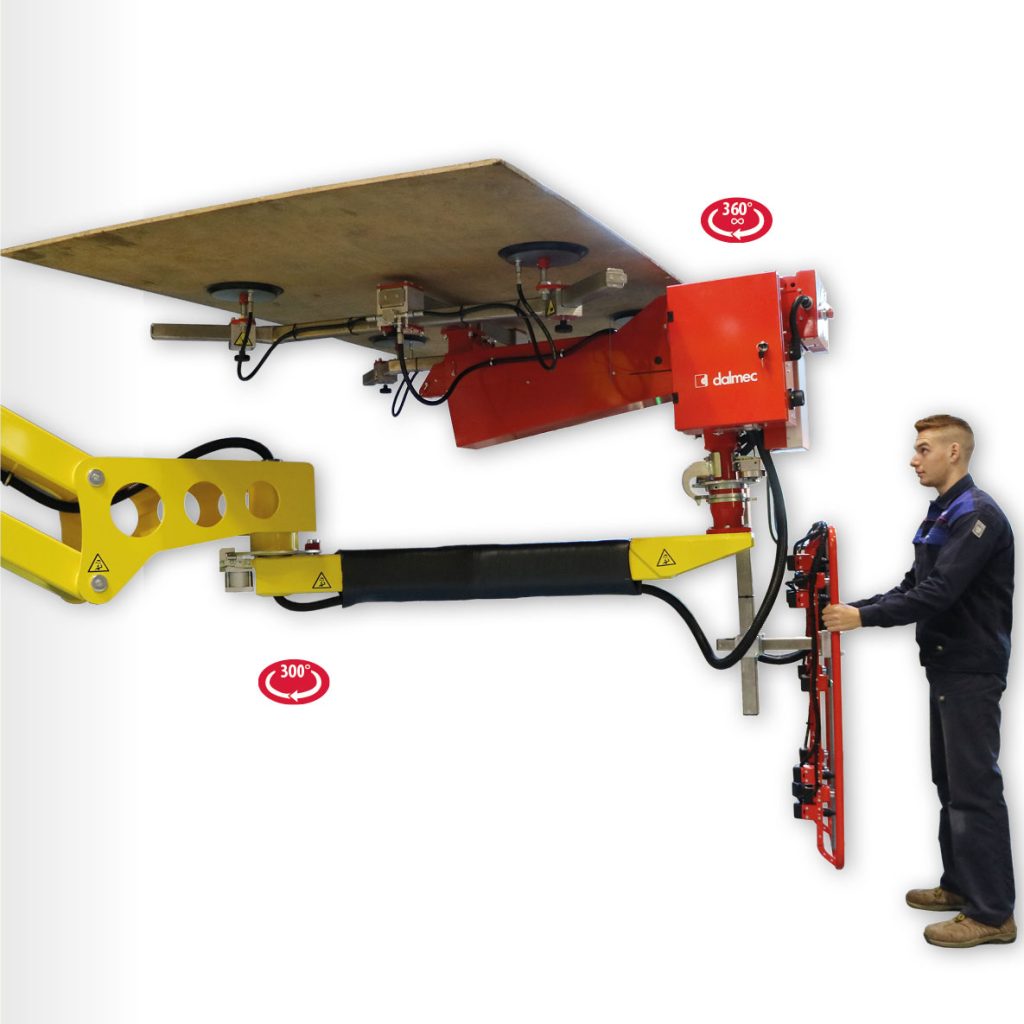

MANIPULATOR WITH ARTICULATED ARMS MAXIPARTNER EQUO ME

Pneumatic Manipulator MAXIPARTNER EQUO ME with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 900 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions.

Its slim and strong structure eliminates the “drifting” effect.

OPERATION

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied.

The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced.

The operator can change the load level simply operating a pneumatic control lever.

| Fixed plate for floor anchoring | Autostable base-plate for forklift truck | Autostable base-plate for pallet truck |

|  |  |

Anchor flange

The pneumatic manipulator fixed overhead version allows to eliminate any floor obstructions.

The flange of the Manipulator is supplied with holes for the anchoring with screws to a strong plate to the ceiling or to a shelf.

All movements are free and are obtained with minimum effort by the direct action of the operator on the gripping tooling or on the load.

Anchor

The Manipulator is supplied with an overhead trolley to run in a tracking system.

Tracking system

The tracking system is composed of two opposite aluminium U sections with connecting and stiffening ribs,complete with attachment points for an overhead suspension and end buffers. The junction between the various parts is done with screws.

Attachment

The attachment of the tracking system to the supporting structure is carried out by means of rods and suspension brackets